A technician, or test engineer, often wants to avoid introducing an additional mechanical component when performing torque measurement on a rotating machine.

Either because he will have to integrate a torquemeter on the shaft line, or because he will embark on the shaft itself a measuring element coupled with telemetry and thus risk inducing an unbalance.

The current market offers solutions but these find their limits when the machine starts to reach high speeds or when there is not enough space to install an additional element on the shaft.

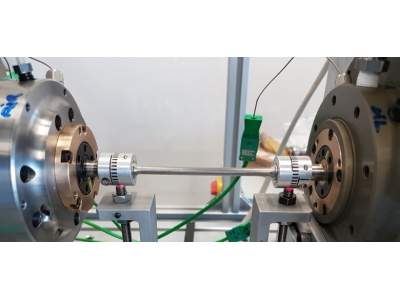

OPTEL-TEXYS answers these problems thanks to its non-invasive fibre optic sensors. Our solution, combined with partner software, allows us to push the current limits very far.

We invite you to discover it during the 9:30 am meeting, presentation session organized by the Réseau Mesure on February 26th.

Inscription : https://www.mesures-solutions-expo.fr/conferences ✍️