Sensorsysteme sind die Referenz in diesem Bereich.

Warum sollten Sie OPTEL-TEXYS optische Tachometer verwenden?

- Wegen ihrer großen Bandbreite und ihrer geringen Reaktionszeit, die es Ihnen ermöglichen, sehr schnelle und hochfrequente Phänomene zu "erkennen ".

- Weil Lichtemission und -detektion unabhängig sind und nicht von einem internen Taktsignal abhängen: Sie verlieren keine Informationen aufgrund einer Detektionspause, während der Lichtemission.

- Wegen der geringen Phasenverschiebung und der Stabilität, der an das Erfassungssystem übertragenen TTL-Signale, auch bei starken Drehschwingungen.

- Wegen ihrer Fähigkeit, sehr hohe Auflösung und einfache Integration in engen Umgebungen zu kombinieren

- Durch die Beschaffenheit der faseroptischen Sonden, die eine Immunität gegen elektromagnetische Wellen bietet und den Einsatz in ATEX-Zonen ermöglicht.

- Detektion in Flüssigkeiten oder Ölnebel.

Für welche Anwendungen ist es notwendig, die leistungsstärksten Sensoren auf dem Markt einzusetzen?

- Erkennung von Azyklismus und Leistungsverbesserung

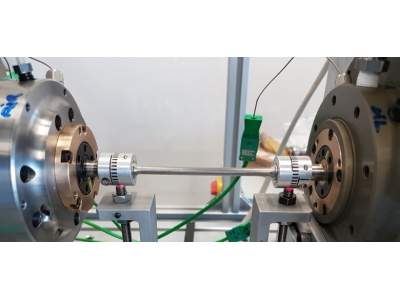

- Messung von Drehschwingungen für die Diagnose und die Suche nach kurativen und präventiven Lösungen

- Analyse der Spitzenverschiebung an Turbomaschinenschaufeln

- Berührungslose Messung des dynamischen Drehmoments

- Auswuchten von Turboladern und sehr schnell drehenden Systemen

- Lageranalyse durch Kugelerfassung im Einweglichtschrankenmodus.

Und mehr...

Zögern Sie nicht, sich mit uns in Verbindung zu setzen. Unser technisches und kommerzielles Team steht Ihnen gerne zur Verfügung, um Ihre Fragen zu beantworten.