Detection in Hot Environments with Optical Fibre Sensors

Offering an assembly comprising a sensor and an optical probe is an appropriate response when the measurement environment is restrictive.

This solution avoids prolonged exposure of the sensor to constraints such as temperature, humidity, electromagnetic interference and an explosive atmosphere. In addition, keeping the electronics close to the acquisition system maintains a good quality incoming signal with little phase shift.

Only the fibre optic probe can withstand extreme environments. Electromagnetic wave immune and not dangerous in HAZOP areas, the design work usually involves protecting it from the effects of temperature, which can sometimes be coupled with vibration fatigue.

Before presenting solutions offered by OPTEL-TEXYS so that its probes can be used at high temperatures, it is worth remembering that the optical fibre of which they are made has a stress memory. Thus, following multiple exposures to mechanical and thermal stress, the optical fibre loses its capacity to transmit light.

Optical probes therefore have a lifetime whose limits are related to their environment and for certain applications, it is necessary to plan a replacement to continue to carry out detection.

Standard OPTEL-TEXYS probes operate in the following temperature ranges:

- Long life: -5°C to +80°C. Some customers have been using probes for over 10 years.

- Limited life: -50°C to +120°C

- Between 120°C and 200°C, protective solutions are offered to cover the exposed part of the probe. However, the lifetime remains limited.

High Temperature Probe: MULTI SLIT YO HT

In these cases, pushing the limits of the OPTEL-TEXYS design in hot environments has the advantage of keeping:

- The same interface with the 152 series sensors

- The ability to conform the probes to specific designs, including reduced bend radii.

For particular high temperature applications with extended lifetimes, our recent R&D work has led us to consider probe designs suitable for temperatures above +200°C.

The first step concerns the study and design of a prototype fibre-optic probe meeting the following specifications:

- Connect to the 152 sensors via adapted rivets

- Transmit without loss the emitted and receipt signals in the IR and near IR

- Be fitted with a standard HM6 threaded ending.

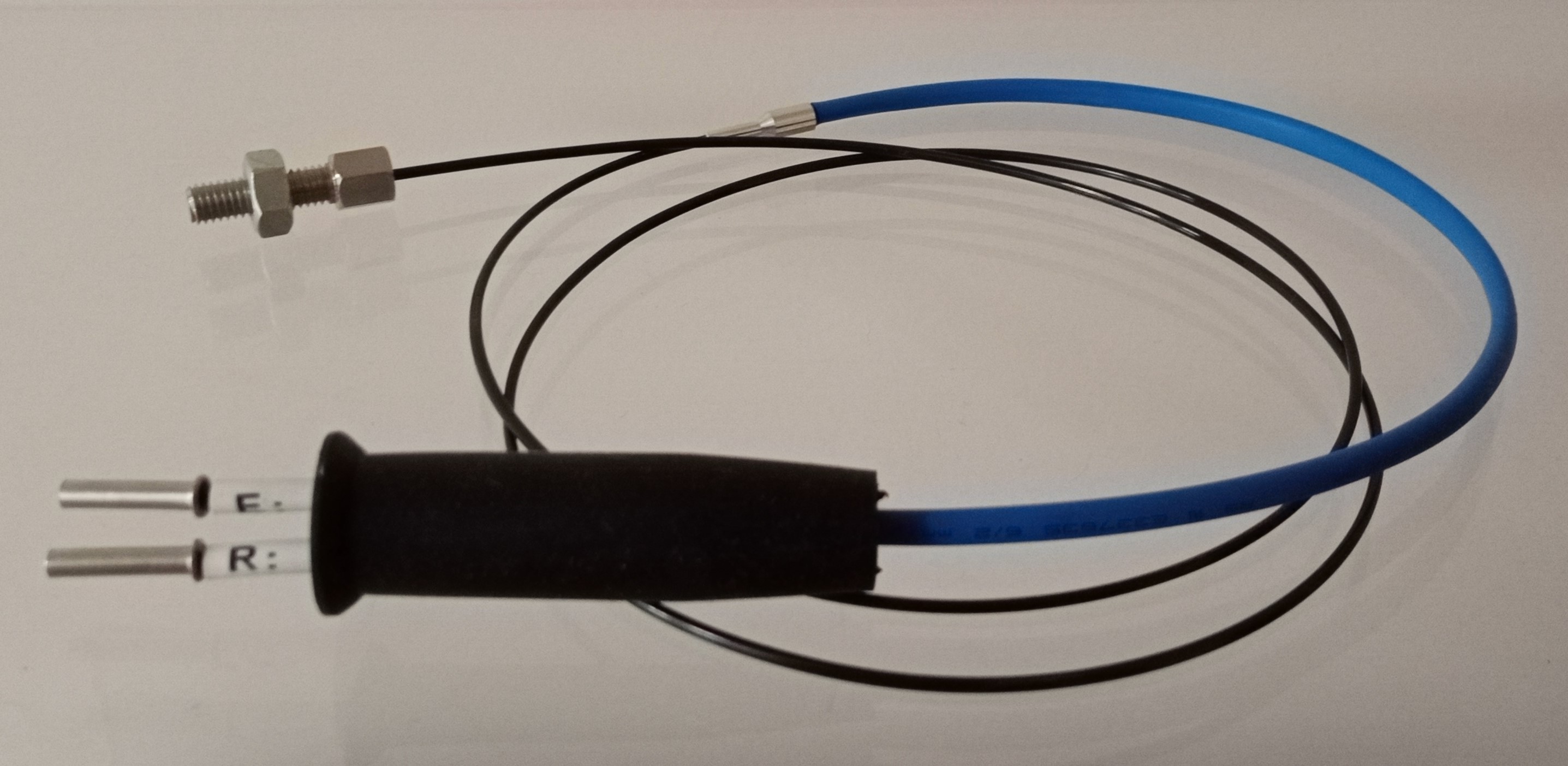

This led to the manufacture of the prototype probe below:

After a series of tests at room temperature, we were able to note:

- A good interfacing with the 152 series sensors

- The ability to detect on metal parts with a detection step equivalent to our SLIT YO probes

- The need to work with a certain number of optical fibres in the composition of the bundles in order to optimise the detection distance.

Our tests are continuing in order to evaluate the life of the probe over a long exposure to +200°C, the protection of this prototype having been chosen initially for this maximum temperature.

In a second phase, we have identified existing products used by our customers. The aim is to interface "high temperature" probes so that our customers can benefit from the performance of the 152 sensors.

The probes presented below are designed to withstand temperatures up to +500°C. We have only tested them for mechanical interfacing and optical transmission.

These probes are equipped with ST connectors as shown in the photo below:

We have designed an adapter to link the ST connectors to our sensors. It has these connectors on one side and the rivets normally used on our optical probes on the other.

Feasibility tests with the 152 G7 and 152 M sensors were inconclusive.

It appeared necessary to inject more light power into the probe to counteract the small optical coupling area.

Using an external 1mW laser source connected to the probe's emission channel, we were able to obtain satisfactory detections.

These tests show that it is possible to benefit from the performance of our electronics by using high-temperature optical probes that were not originally intended to work together.

In conclusion, we found that while it was possible to use customers’ probes, it was important to take into account the interfacing constraints in order to generate and transmit sufficiently high levels of light to ensure correct detection.

In the first case, the bundle of optical fibres must be designed to achieve a high coupling surface. In the second example, the solution is to use a light source external to the sensor.

As each case is unique, our R&D teams are ready to study and propose the appropriate solution to enable you to use OPTEL-TEXYS sensors.